This entry in the P&L Workshop Diary is all about modern cars, renovations and restorations. It’s the kind of work we love doing – taking cars that are feeling a little bit under the weather and turning them back into the beautiful driving machines we know they can be. Read on to find out exactly how we’ve been making that happen….

We focus on a number of new cars in this report although actually, the definition of ‘new car’ is pretty loose, to be honest. For example, we’ve spent quite a lot of time working on a blue DB4 that we’re trying to get up and running – not to mention looking fantastic – in time to hit the tarmac for at least some of this summer. It’s a car we’ve mentioned before and it’s genuinely multi-national in nature because it was purchased at auction in France by an Australian customer. It’s a left hand drive vehicle and we’ve been undertaking a mechanical restoration for the last two months or so.

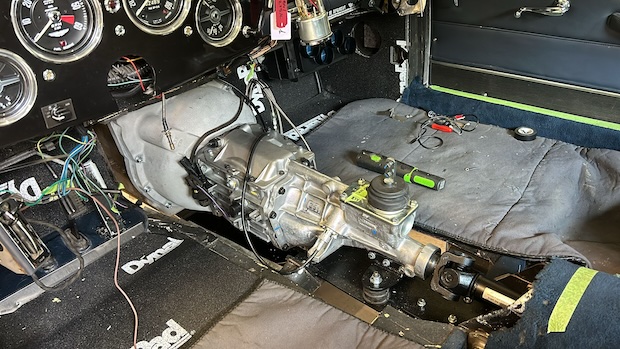

Right now, with the clock ticking for a summer deadline, we’re working on it flat out, sometimes three of us at a time making sure that we get it over the line. We’ve already put a new gearbox in as well as rewiring and installing soundproofing, heat proofing and air-con. As if that’s not enough it’s going to have power steering, and we’re making sure the brakes are good. The problem with the brakes as they were is that, being a DB4, the vehicle had less efficient brakes in place than a DB6 or a DB5, so we’ve upgraded them to make sure they work as well as in the later vehicles.

The main aim of a mechanical restoration of this type is making sure that the engine runs well, which is obviously sometimes easier said than done, but even that’s not always the full story. As well as everything already mentioned, for example, we have to do things like making sure the fuel systems are reliable. In a lot of the older cars, the fuel gauge will be telling you that everything’s alright and they’ve got fuel in the tank but, in reality, you’re about to run out or you’re running onto reserve, which is obviously not ideal. So, it’s a simple little thing, but making sure the gauge reflects what’s actually happening in the vehicle is pretty important, because the alternative is finding yourself on the side of the road with an empty tank, at which point it won’t really matter how beautiful your car looks.

One of the interesting aspects of this particular job was that it illustrated the balance we have to strike between what a customer might want for their vehicle and what we, as mechanics, understand is most important in terms of getting that vehicle running as well as possible. The process involves the customer letting us know a few things they’d like and then we, after getting a proper look at all aspects of the vehicle, coming back with a list of things which we feel are critical in terms of making the car we’re working on the car the customer wants to be driving. Between us and the customer we’re then able to draw up a definitive list of things that absolutely need to be done, and then a few more things that the customer would quite like us to do.

We haven’t really had to touch the paintwork or the interior of this vehicle but we can honestly say that right now, after all the work we’ve put in, it’s starting to look like an actual car again, and by the time we’ve finished every little detail it’s going to be lovely.

As well as the left hand drive DB4 we’ve been working on a black V8 Vantage dating from around 1977, which was brought in for a service and checkout because it wasn’t running that well. This is a really early Vantage which the customer in question has had since it was brand new, and they were keen to get it back on the road and running as nicely as he knew it was capable of doing.

What we discovered once we got to work on the engine was that the problem lay in the cylinder heads. After carrying out a compression test, we found low compression in two cylinders on the left bank – on removal and inspection of the cylinder head we conversed with the customer and confirmed that both cylinder heads should be removed in order to carry out decoking as well as overhauling to unleaded specification - with all new valves and valve springs.

While the cylinder heads are removed we will take the opportunity to refurb the engine bay to return it to its former glory!

As well as the satisfaction of getting these particular cars up to speed, if you’ll pardon the pun, it’s been very nice to see our new lad, Ben, really getting hands on with the work we had to get through. In the main, Ben has been helping Dan with the left hand drive DB4, and this kind of practical experience is invaluable when it comes to getting to know exactly what makes the Aston Martins tick. The more experience he gets, the more able we are to work on a number of complex restoration or repair jobs simultaneously, delivering multiple projects for our customers who are always understandably keen to get their vehicles back on the road as quickly as possible. By the time we write our next diary entry there’s a pretty good chance that the left hand drive DB4 and the black V8 Vantage will be back where they ought to be – on the road.